MOBILE APPARATUS

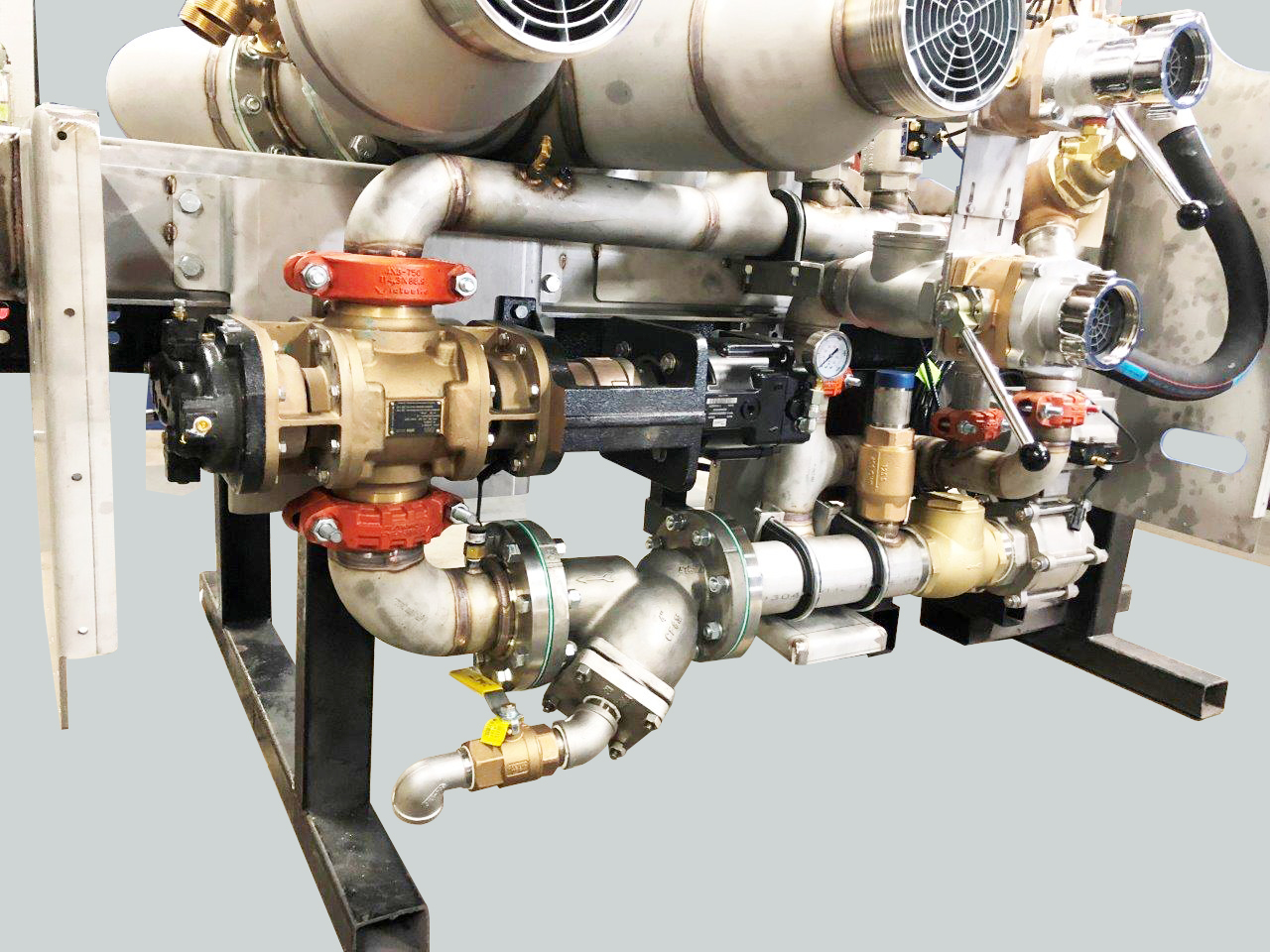

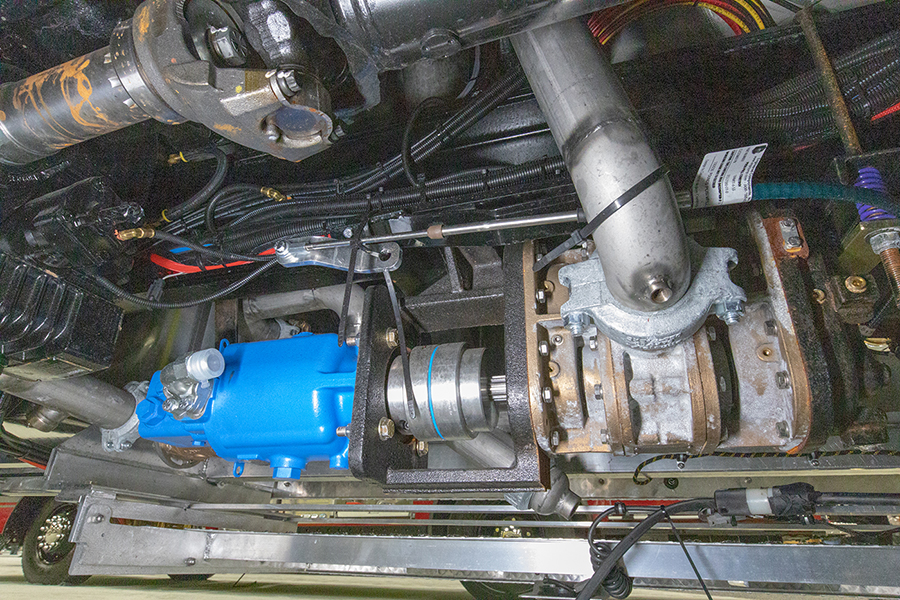

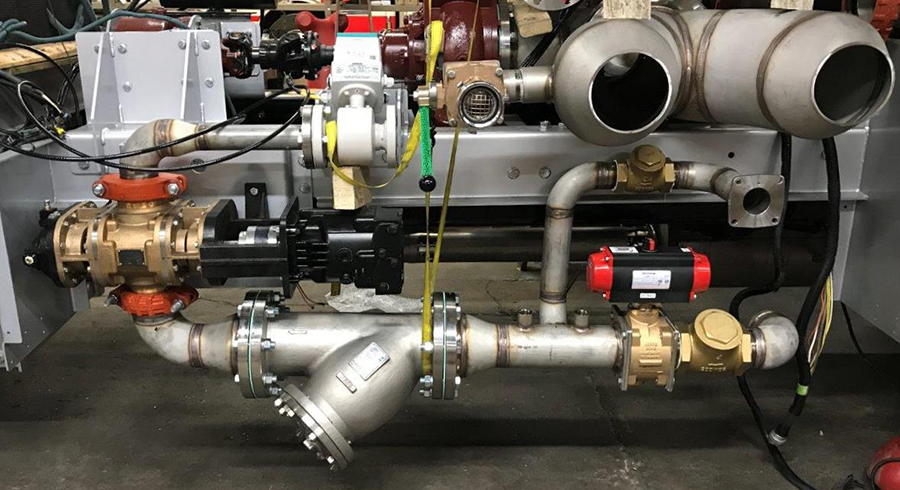

Foam Pump Retrofit GuideFoam pumps operating on mobile apparatus see some of the toughest use, operating for long durations, ever changing speeds, pressures, flows, and have to endure the potential run dry situation. The Trident GP Series positive displacement, rotary gear foam pumps are perfect for any mobile apparatus application, whether hydraulic drive or PTO driven. Rugged design allows for continuous operations up to 300 PSI (20.7 Bar), with a timing gear drive system to eliminate rotor wear and overheating in dry run situations. Whether the application is a balanced pressure system, flow-meter based direct injection system, or as a transfer pump for nurse tankers, Trident offers a GP Series foam pump suitable for your needs.

And, if you are struggling with an old, worn-out, leaky foam pump, please contact us, we've got a pump to take care of that problem too. Our GP Series foam pumps are easily adaptable to your configuration and are fire ground proven.

The ITC facility chemical fire in Deer Park, Texas that burned from March 17th through the 20th, 2019 was a major incident requiring the resources of over 1,000 firefighters and dozens of apparatus from companies in the surrounding area. Several days of continuous, extensive, and difficult firefighting were required to control and extinguish this blaze resulting in the damage and destruction of several storage tanks and surrounding piping. Trident is proud to announce that several of the front line industrial apparatus were equipped with the Trident GP Series foam pumps suppling foam concentrate to the foam proportioning systems. According to the Chief of one supporting company, they responded with three apparatus, all equipped with Trident foam pumps.

“I can’t begin to tell you how well these Trident foam pumps have performed. I had multiple foam engines involved in the ITC fire. We have had ZERO issues and the foam pumps coupled with the foam system… it is second to none. In a rough calculation… I discharged over 25k gallons of concentrate through just one of the three Trident pumps. Obviously during the fire we were off and on in foam ops… one of my engines had over 55 continuous hours of water pump time. All 3 engines were involved in the extinguishment of that fire. I am seeing a better reaction time on foam pressure, better balances, and overall quietness during operation. I have historically run other foam pumps, but that is until I went with the GP-Series pumps from Trident. I’m always skeptical trying new equipment but I haven’t looked back. I also think the price point is spot on. Further, I am looking to build 2 foam tenders and those will be sporting the Trident foam pumps as well. This is a great product and I have been sharing my success with others in the industry. I highly recommend these battle proven pumps”.

• All Bronze and Stainless Steel Construction

• Compatible with all foam concentrates

• No internal plastic parts

• Timing gear rotor drive system

• Oil bath splash lubrication

• No rotor to rotor contact

• No grease required

• Extended dry run ability

• Sealed double row spherical roller bearings

• No open race ball bearings which require grease

• No pump shaft sleeve bushings that do not receive proper lubrication

• Mechanical pump seals

• No foam concentrate contact with pump shafts

• No lip seals to fail and leak

• EPDM square seals between body and heads

• Material compatible with all foam concentrates

• No paper gaskets

• Pumps feature Victaulic™ port connections, not threads

• Train, test and calibrate with water at full pressure and speed

• All pumps operate up to 300 PSI [20.7 Bar]