BALANCED PRESSURE FOAM SYSTEM COMPONENTS

Metering Valves, Ratio Controllers (Proportioners), System Balancing Valve, Relief Valves and more.

Piecing Together a Foam Firefighting Delivery System

Create a Customized Balanced Pressure Foam System with Trident's GP Series High Performance Rotary Gear Foam Pumps and Components Designed to Perform Together

METERING VALVES

A metering valve is utilized in conjunction with a ratio controller to control the foam injection percentage (%). The metering valve acts as an adjustable orifice that can be set and calibrated with a specific ratio controller to compensate for losses within the foam concentrate piping, creating accurate injection across the ratio controller’s flow range. Each metering valve is sized to match the flow requirements of the specific size ratio controller and can be calibrated for up to 6% injection rates. All valves are easily installed using industry standard pipe groove connections (Victaulic™).

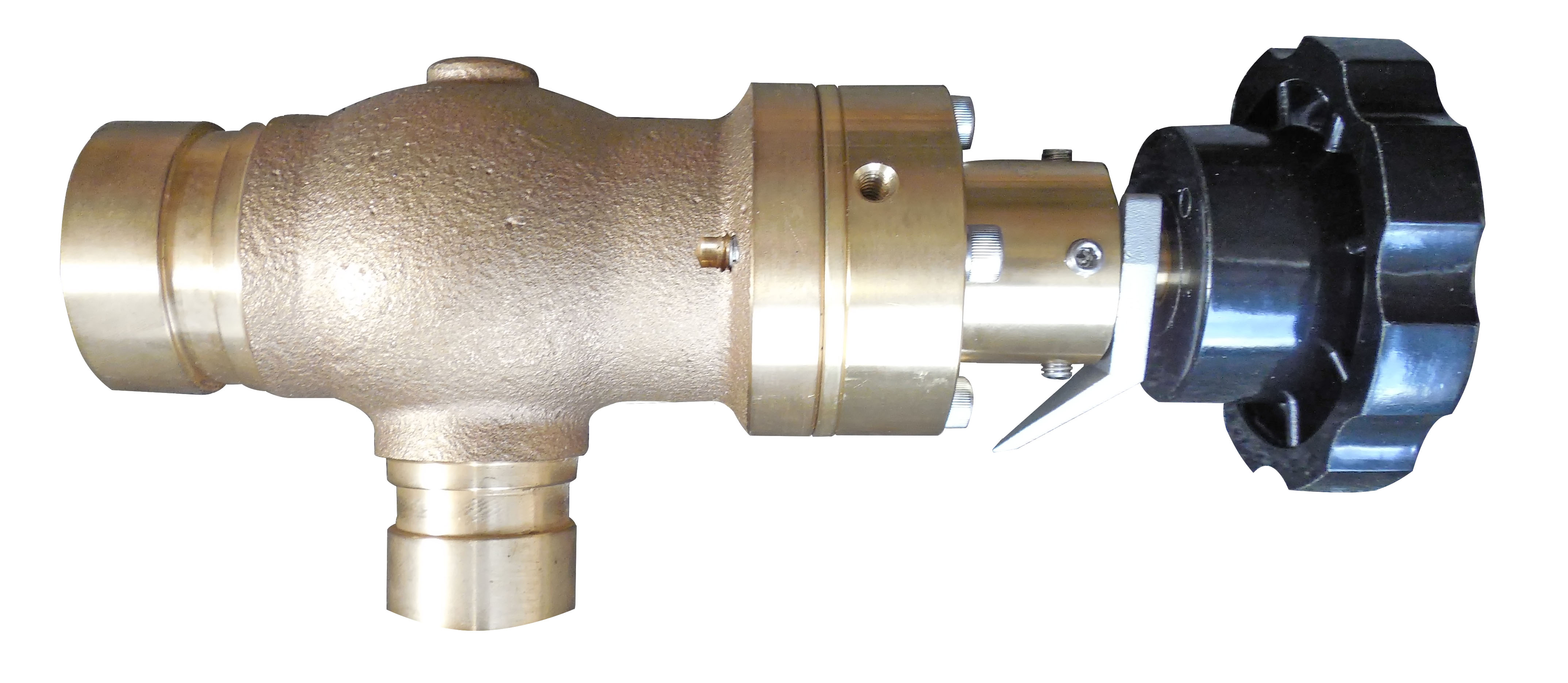

METERING VALVE DATA SHEETRATIO CONTROLLERS

Trident 2", 2.5", 3", 4" and 6" [50.8, 63.5, 76.2, 101.6 and 152.4 mm] ratio controllers, or proportioning devices, are designed to accurately inject pressurized foam concentrate into a water stream with minimal pressure loss, over a wide range of flows and pressures, when used in conjunction with the matching foam concentrate metering valve. Proper proportioning of foam concentrate into the water stream is maintained through the operating range of the ratio controller, without any manual adjustment to the device, by simply maintaining a balanced pressure between the water and foam concentrate. Trident ratio controllers are compatible with any type of foam concentrate, including fluoroproteins, thixotropic, and fluorine-free. See data below for operating flow ranges, dimensional information, friction loss curves and minimum inlet pressure.

2" - 4" RATIO CONTROLLER DATA SHEET6" RATIO CONTROLLER DATA SHEETBALANCING VALVE

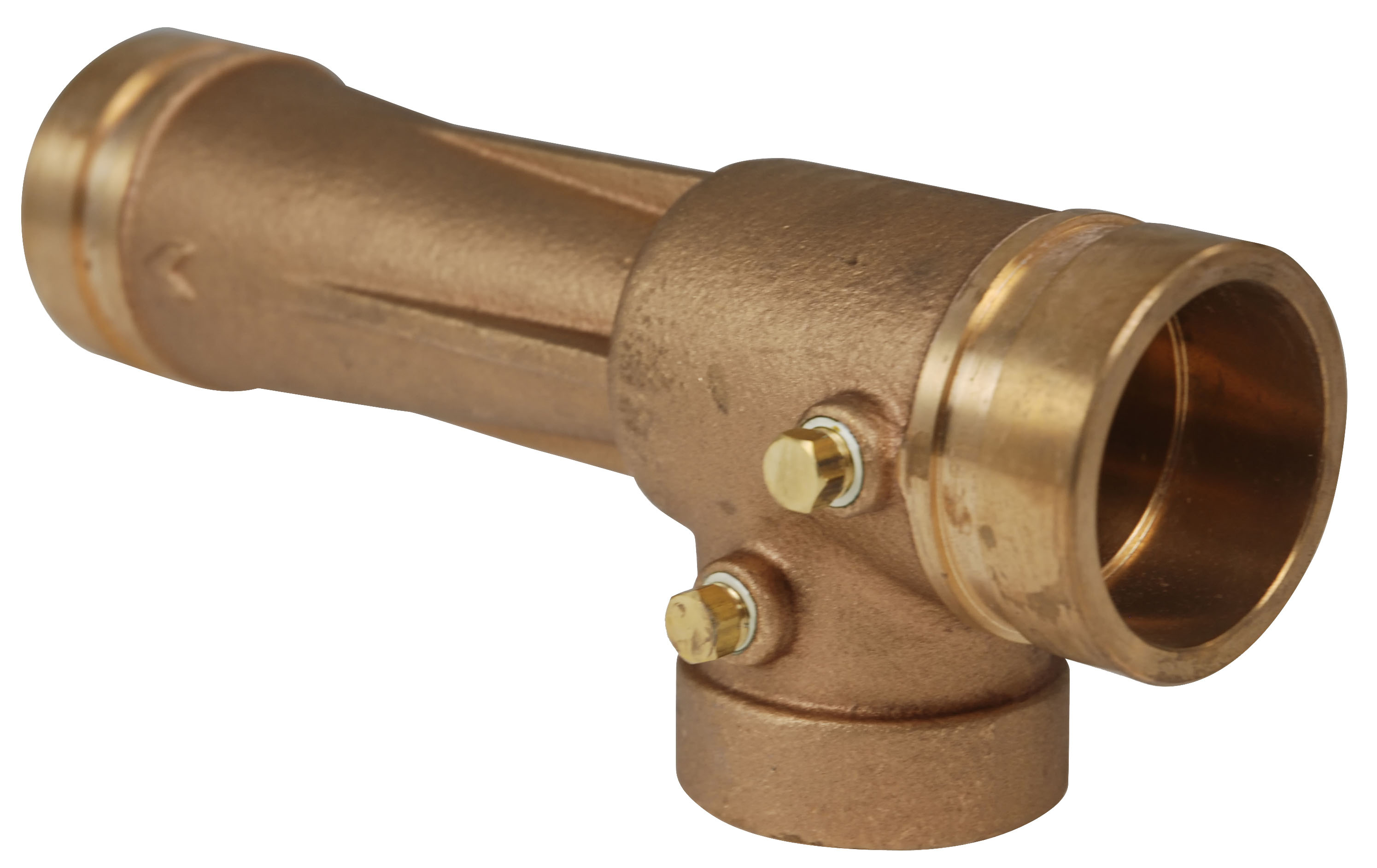

A 2" [50.8 mm] Balancing Valve is the key component in a balanced pressure type foam proportioning system. The Balancing Valve maintains a balanced foam concentrate pressure to that of the water supply pressure at the inlet of the foam proportioner (ratio controller).

Balanced pressure between the water supply inlet and the foam concentrate pressure at the balancing valve is controlled by the amount of foam concentrate the balancing valve regulates and returns to the foam storage tank. The Balancing Valve utilizes an extremely simple design to obtain a balanced water to foam concentrate pressure, providing reliability and repeatability – a design of only two internal moving parts.

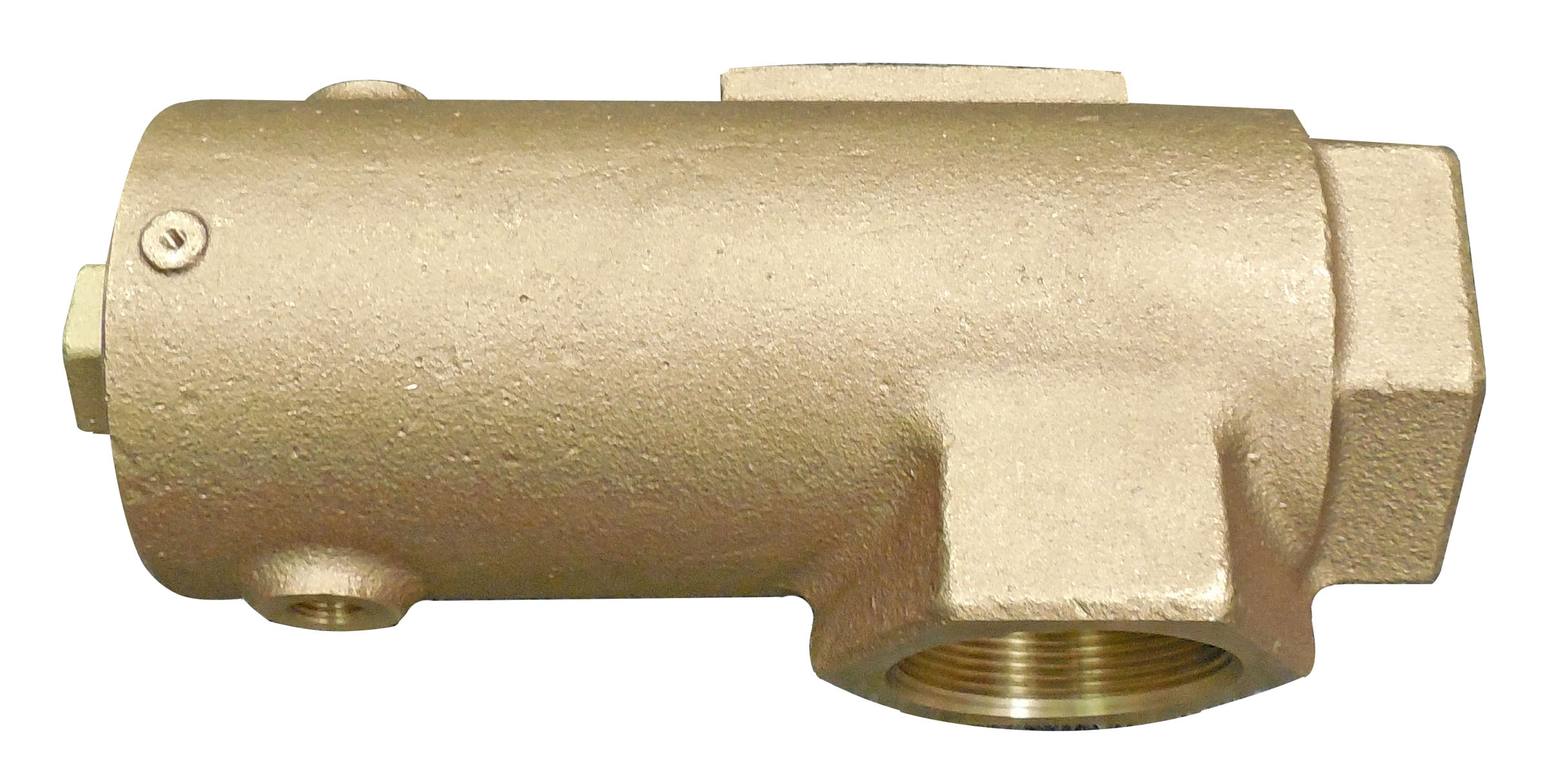

CHECK VALVES

Class 150S bronze, horizontal swing type check valve with female NPT threaded piping connections. All wetted parts are cast bronze or brass. Suitable for all types of foam concentrates, including fluoroproteins and thixotropic types. Will operate with fresh, brackish, or seawater. Valve body connections are female NPT, per below chart.

RELIEF VALVES

The NFPA 20 Standard requires that a safety relief valve to be installed on the discharge side of foam pumps as a mechanism to prevent system over-pressurization for protection of personnel and property. The relief valve must be sized to relieve 100% of the rated pump capacity at a pressure not exceeding 125% of the relief valve set pressure. Trident offers safety relief valves specifically designed for foam fire protection systems utilizing a positive displacement foam pump, and a relief valve is available for each size Trident GP Series Foam Pump offered.

BALL VALVES

Manually operated, nickel plated brass ball valve in full port configuration with chrome plated ball. Valves are provided with PTFE seat and stem packing, with female NPT threaded piping connections. Manual operation lever provided with full closed to full open in 90° (quarter

turn). Suitable for all types of foam concentrates, including fluoroproteins and thixotropic types. Available sizes are: 1.0" [25.4mm], 1.5" [38.1mm], 2.0" [50.8mm], 2.5" [63.5mm], 3.0" [76.2mm] and 4.0" [101.6mm].

BP Gallery